Subaru’s are, in general, pretty robust cars. They make good power, are easily upgradeable, work well at the track at at autocrosses and can haul your family around in safety. Like most cars, they do have some common issues to watch out for. Here are some of the highlights:

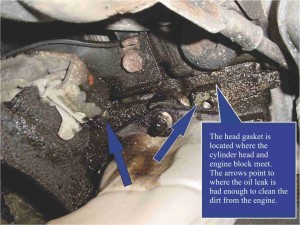

Non turbo SOHC 2.5L 4-cylinder head gaskets came from the factory with a single layer steel HG with a coating that deteriorates over time. This causes external oil and coolant leaks. Every last SOHC 2.5 we have seen has this issue, even the brand new ones.

Non turbo SOHC 2.5L 4-cylinder head gaskets came from the factory with a single layer steel HG with a coating that deteriorates over time. This causes external oil and coolant leaks. Every last SOHC 2.5 we have seen has this issue, even the brand new ones.

Misfires on the turbo 2.5L EJ255/257. Symptoms can range from vacuum/boost leaks, cracked ringland on the pistons or even tight exhaust valve clearances. Ignoring the misfire which 9 times out of 10 is a tight valve can lead to burnt valves and much bigger problems/more expensive. The tight valve clearance develops over time due to many heat cycles. The valve stems grow and shrink the gap between the cam and cam followers. You want to catch this issue early!

Misfires on the turbo 2.5L EJ255/257. Symptoms can range from vacuum/boost leaks, cracked ringland on the pistons or even tight exhaust valve clearances. Ignoring the misfire which 9 times out of 10 is a tight valve can lead to burnt valves and much bigger problems/more expensive. The tight valve clearance develops over time due to many heat cycles. The valve stems grow and shrink the gap between the cam and cam followers. You want to catch this issue early!

Cracked radiators just like BMW’s. The cracks on the plastic endtanks and visible coolant is present. Usually occurs after or around the time the timing belt needs changing (105k service). We suggest changing the radiator and hoses at the same time to alleviate the head aches of a leaky/failed radiator after the 105k was just performed. This happens on both Turbo and non-turbo Subies. It should also be noted at all coolant services on a Subaru MUST include a bottle of the factory Blue additive.

Cracked radiators just like BMW’s. The cracks on the plastic endtanks and visible coolant is present. Usually occurs after or around the time the timing belt needs changing (105k service). We suggest changing the radiator and hoses at the same time to alleviate the head aches of a leaky/failed radiator after the 105k was just performed. This happens on both Turbo and non-turbo Subies. It should also be noted at all coolant services on a Subaru MUST include a bottle of the factory Blue additive.

Wheel bearings. Very common issue usually occurring around 80k. Symptoms are Humming, grinding, or thumping when the bad wheel bearing is being loaded.

Wheel bearings. Very common issue usually occurring around 80k. Symptoms are Humming, grinding, or thumping when the bad wheel bearing is being loaded.

Oil consumption. Common with the 2.5L Turbo motors, it can be caused by cracked piston ring lands due to Subaru using weak Cast pistons. Symptoms are down on power, smoking under acceleration, oil consumption, excessive blow-by. Failure to notice the symptoms can lead to catastrophic engine failure. I.E. spun rod bearings, seized cams, and turbo failure.

Oil consumption. Common with the 2.5L Turbo motors, it can be caused by cracked piston ring lands due to Subaru using weak Cast pistons. Symptoms are down on power, smoking under acceleration, oil consumption, excessive blow-by. Failure to notice the symptoms can lead to catastrophic engine failure. I.E. spun rod bearings, seized cams, and turbo failure.

Spun rod bearings. All Subaru 4-cylinder engines are susceptible to this. Symptoms are metallic knocking noises coming from the engine during cold start, or if the bearing is destroyed enough, the knock can be audible when warm. Failure to check and maintain oil level can lead to rod bearing failure.

Spun rod bearings. All Subaru 4-cylinder engines are susceptible to this. Symptoms are metallic knocking noises coming from the engine during cold start, or if the bearing is destroyed enough, the knock can be audible when warm. Failure to check and maintain oil level can lead to rod bearing failure.